Time:

When you supply catering companies, foodservice brands, or institutional kitchens, capacity, consistency, and reliability directly affect your business results. Therefore, choosing the right full size aluminum foil pans is not just a product decision—it is a strategic one.

Compared with half-size or small containers, foil pan full size products are designed for high-volume cooking, storage, transport, and reheating. As a result, they have become a core SKU for international distributors serving hotels, airlines, central kitchens, and large-scale takeaway operations.

In this guide, you will clearly understand dimensions, depth options, material selection, lid compatibility, and market demand. More importantly, you will learn how to choose the right aluminum foil pans 21x13 for your customers and your market.

First of all, full size steam table pans are disposable aluminium foil containers manufactured according to globally accepted catering standards. Because of this standardization, they fit seamlessly into professional kitchen equipment.

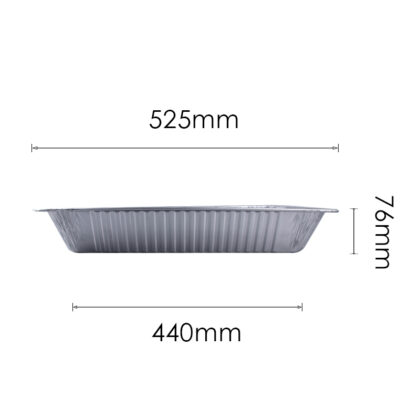

The dimensions of a foil pan full size are as follows:

For this reason, buyers around the world commonly refer to them as aluminum foil pans 21x13.

Since these dimensions match ovens, steam tables, warming cabinets, and chafing dishes, you can confidently distribute full size pans across different regions with minimal compatibility risk.

Next, it is important to understand why aluminum foil pans 21x13 dominate international foodservice markets.

Because professional kitchens rely on standardized equipment, chefs expect containers that fit perfectly without adjustment. Therefore, the 21x13 footprint became the default choice for bulk food preparation and service.

As a result, foil pan full size products are not seasonal or trend-based items—they are long-term, high-volume essentials.

Although length and width remain consistent, depth determines application, capacity, and value. Therefore, understanding depth options helps you build a balanced product portfolio.

Full size shallow aluminum pans usually have a depth of 33–38 mm. Because of their low sidewalls, they allow fast heat transfer and even baking.

Since shallow pans use less aluminum, they are more cost-effective. Consequently, they work well in price-sensitive markets and high-frequency baking applications.

Full size medium aluminum pans typically range from 44–48 mm in depth. Therefore, they offer a practical balance between capacity and handling convenience.

Because they are neither too shallow nor too deep, medium pans suit a wide range of customers. As a result, they are often included as core SKUs in distributor catalogs.

Among all depth options, full size deep aluminum pans are the best-selling SKUs in the categories.

With depths typically between 67–72 mm, these pans provide maximum capacity while maintaining the standard 21x13 footprint.

Because deep pans reduce the need for multiple containers, they improve operational efficiency. Therefore, catering companies and central kitchens strongly prefer them.

To help you choose the right products, the table below compares shallow, medium, and deep full size foil pans.

| Type | Top Dimensions (L × W) | Depth | Typical Applications |

| Full Size Shallow Aluminum Pans | 20¾ × 12¾ in (525–530 × 325–330 mm) | 33–38 mm | Baking, vegetables, buffet display |

| Full Size Medium Aluminum Pans | 20¾ × 12¾ in (525–530 × 325–330 mm) | 44–48 mm | Pasta, casseroles, mixed meals |

| Full Size Deep Aluminum Pans | 20¾ × 12¾ in (525–530 × 325–330 mm) | 67–72 mm | Soups, bulk meals, airline catering |

This standardized sizing makes aluminum pans full size easy to trade and explain to international buyers.

In addition to the pan itself, lids play a critical role in food safety and transport.

However, it is important to clarify one key point:

Foil pan full size do NOT use board lids with foil lining.

These lid types offer better sealing, higher heat resistance, and safer stacking. As a result, full size aluminum pans with lids support takeaway, delivery, and bulk food transport more effectively.

Material quality directly affects performance and customer satisfaction. Currently, foil pan full size now use 3004 aluminum alloy as the mainstream choice.

Because of these properties, 3004 alloy is especially suitable for foil pans full size, where structural stability is essential.

Besides alloy type, foil thickness also matters.

Although thicker foil increases cost, it significantly improves durability. Therefore, choosing the right thickness helps you match product performance to real-world usage.

Proper packaging protects the product and improves logistics efficiency.

Well-designed packaging prevents deformation during shipping and enhances your professional image. Consequently, it supports long-term partnerships with overseas buyers.

For international trade, compliance is essential.

Most high-quality aluminum pans full size meet:

By ensuring compliance, you reduce regulatory risk and increase buyer confidence.

From a commercial perspective, foil pan full size products offer clear advantages:

As a result, they generate consistent volume and predictable sales.

Finally, you should evaluate your customer base carefully.

By answering these questions, you can select the most suitable aluminum foil pans 21x13 and build a competitive product lineup.

In conclusion, aluminum pans full size are essential tools for modern foodservice operations. Whether you distribute foil pan full size products for catering, supply full size aluminum pans with lids for takeaway, or focus on full size deep aluminum pans for bulk food preparation, choosing the right specifications creates long-term value.

By understanding dimensions, depths, materials, and market demand, you position yourself as a knowledgeable and reliable partner. Ultimately, when you align product quality with real customer needs, you strengthen your brand and grow your international distribution business.

Related News

Get A Free Quote

Submit Request