Time:

The global food packaging industry continues to grow rapidly, and aluminium foil containers have become an essential solution for food service, catering, and retail. With increased demand for ready-to-eat meals, delivery services, and takeaway options, businesses across the globe are turning to aluminum trays for their lightweight, recyclable, and heat-resistant qualities.

If you are an importer, wholesaler, or food packaging distributor, understanding the aluminium foil container wholesale price is crucial. This guide explores the factors that affect bulk pricing, how to select the right raw materials, and how to negotiate better deals from manufacturers.

Let’s dive into what shapes the cost of disposable aluminum trays and how you can optimize your supply chain in 2025.

Understanding the variables that determine pricing is the first step toward making smart purchasing decisions.

At the heart of every aluminum foil container is the raw aluminum itself. Wholesale prices fluctuate with the London Metal Exchange (LME), where aluminum is traded globally. Prices also vary based on whether the foil is made from primary aluminum or recycled aluminum.

Manufacturers typically use the following aluminum alloys:

Choosing the right alloy can impact both tray performance and your final cost. Manufacturers usually recommend alloys based on your tray shape and usage.

Thicker foil requires more material and energy to produce. As such, the micron level of the foil directly influences the wholesale price. Common thicknesses range from:

Heavier trays offer more strength, but they also cost more. To save money, buyers should match thickness to the intended food type and transport conditions.

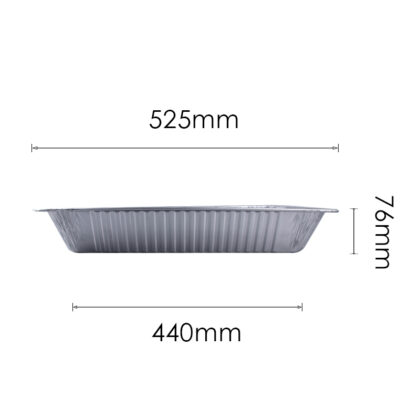

The larger the container, the more raw material it consumes, and the higher the cost. Complex shapes (multi-compartment trays or custom molds) require more tooling and slower production speeds.

Standard shapes, like rectangular or round trays, are more affordable because they use existing molds and efficient production lines. For high-volume purchases, sticking to industry-standard designs helps control costs.

Wholesale pricing always improves with higher quantities. Aluminum foil container manufacturers typically offer tiered pricing, where unit cost drops as order volume increases.

For example:

Always ask for MOQ (Minimum Order Quantity) and price breaks. If you consistently buy large volumes, consider a supply agreement to lock in better rates over time.

Adding lids to your order changes the pricing structure. Options include:

Also, consider how your trays are packed—bulk in cartons, wrapped in plastic sleeves, or shrink-wrapped on pallets. Export-grade packaging and branding increase costs, but they ensure safe transit.

Prices can vary significantly depending on the country of origin, local production costs, and logistics.

China offers the most competitive aluminium foil container wholesale price due to:

As a silver foil container manufacturer, Zhengzhou Eming typically quote EXW (Ex-Works) or FOB (Free On Board) Ningbo or Qingdao port. CIF (Cost, Insurance & Freight) pricing is also available upon request.

India’s foil industry is expanding steadily, driven by domestic aluminum production and increasing demand for food-grade packaging. Major producers like Hindalco and Jindal support a growing supply chain.

While India benefits from local access to primary aluminum, some foil container products—especially deep-drawn or smoothwall trays—may cost slightly more than Chinese equivalents. This is due to higher energy costs, manual labor in forming processes, and less automation in many facilities. However, for basic wrinklewall containers, India can offer competitive or even matching prices depending on order volume and specifications.

In Southeast Asia, countries like Vietnam and Thailand are developing their foil packaging industries but still rely on imported aluminum coil. As a result, they usually provide mid-range pricing and are better suited for regional supply rather than high-volume global export.

Buyers looking for consistent quality and competitive pricing should compare offers from India with Chinese manufacturers, especially when sourcing non-standard or niche designs of aluminum foil trays.

Most trays are imported, which increases landed costs due to duties and shipping. However, for nearby countries (UAE, Saudi Arabia), Jebel Ali serves as a distribution hub for foil packaging.

Local production is limited and expensive. Distributors typically import foil containers from Asia or Turkey. Prices can be 2x higher than Chinese wholesale rates due to compliance costs, duties, and labor.

You can reduce costs significantly with the following strategies:

Long-term cooperation allows you to:

Manufacturers often reward repeat buyers with better payment terms or discounted freight.

Not every job needs the strongest or most expensive alloy. For example:

Let the manufacturer know your usage scenario, and they’ll recommend the most cost-effective alloy.

Avoid custom tray sizes unless necessary. Standard molds result in lower unit costs and faster lead times. Choosing stackable trays also reduces carton and pallet space, lowering your logistics costs.

Ordering lids, foil rolls, and pop-up sheets along with your containers lets you:

Some manufacturers, such as Zhengzhou Eming Aluminium Industry, offer combo deals for catering kits (tray + lid + roll).

Transparency is key. A detailed quote usually includes:

Ask for sample pricing and compare suppliers. For example:

| Specification | Price (FOB China) |

| 450ml tray, 8011 alloy, 40 microns | $0.031/pcs |

| 650ml tray, with paperboard lid | $0.045/pcs |

| 850ml smoothwall tray, 8006, 60 microns | $0.072/pcs |

Several trends are shaping global pricing for aluminum foil trays:

Aluminum prices on the LME remain volatile due to geopolitical issues, energy costs, and mining regulations. Prices may remain elevated throughout 2025.

Shipping prices have stabilized from the COVID-era peak, but oil prices and Suez Canal disruptions still influence logistics costs.

More buyers now request eco-friendly packaging, such as recyclable foil, water-based inks, and biodegradable lids. These options often increase unit cost but help meet retailer and consumer expectations.

When buying wholesale, quality assurance and supply reliability are critical.

Choose a supplier who can meet your order volume and deliver consistently. Ask about:

Make sure your supplier has:

These credentials ensure compliance with international food-grade packaging standards.

If you need branded trays or custom molds, a strong supplier can support:

This adds value to your product line and strengthens your brand in the marketplace.

Wholesale pricing for aluminum foil containers depends on many factors—from raw material selection to packaging and shipping. By understanding the key cost drivers, you can make smarter purchasing decisions and secure better deals from manufacturers.

To recap:

As a trusted manufacturer of disposable aluminum foil containers, Zhengzhou Eming invites you to contact us for a detailed quotation, free samples, or a custom product catalog tailored to your market. WhatsApp: +86 19913889786.

Let’s grow your business together—with quality you can trust and pricing you can depend on.

Related News

Get A Free Quote

Submit Request