Time:

The global food packaging industry continues to grow rapidly, and one segment that's gaining exceptional traction is the aluminium foil container business. With the rise in food delivery services, takeaway culture, and hygiene awareness, aluminum containers have become a staple for restaurants, catering services, and households worldwide. If you are considering entering a profitable, scalable, and future-proof market, this guide will walk you through the key steps to launch your own aluminum foil container business.

First and foremost, the aluminum foil container business is not just another trend — it meets essential needs across multiple industries. Food vendors, supermarkets, airlines, and even home bakers rely on aluminum containers for their durability, heat resistance, and recyclability. With global consumers and businesses shifting towards eco-friendly and single-use hygienic solutions, aluminum foil container manufacturers are seeing increased demand year after year.

Moreover, these aluminum foil trays serve a wide array of uses: from packaging baked goods and grilled items to storing frozen meals. This diversity allows you to cater to various market segments, from small eateries to large distribution companies.

Before starting your aluminium foil container business, it’s crucial to define your business model. Will you act as a local supplier, a contract manufacturer, or an exporter? Will your focus be bulk food packaging, custom-printed containers, or a mix of both?

Also, evaluate your budget and conduct a feasibility study. A small-scale aluminium foil container factory might need an initial investment of $30,000 to $50,000, while a larger operation may require up to $100,000. It's wise to conduct a SWOT analysis to assess your strengths, weaknesses, opportunities, and threats in your target market.

Once you’ve outlined your business model, the next step is establishing your production facility. Choose a location with adequate power supply, transportation access, and compliance with local zoning laws. For a small to medium-sized setup, a facility of 100–300 square meters is generally sufficient.

Key Equipment Includes:

Investing in modern machinery ensures consistent product quality and faster production cycles. Many aluminium container suppliers prefer automated lines that reduce labor costs and increase productivity.

The core material you’ll work with is aluminum foil rolls, typically food-grade 8011 or 3003 alloy with a thickness between 0.035mm to 0.1mm. Ensure your suppliers provide reliable, food-safe aluminum certified by organizations like FDA or SGS.

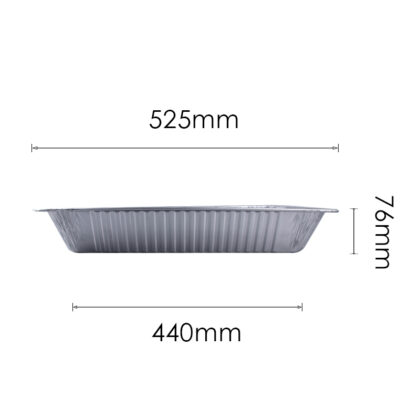

Design your product range based on demand in your market. Common containers include:

Customization options like embossing, logo printing, and custom lid designs can also help you stand out in a competitive market.

Quality is the backbone of a sustainable aluminum foil container business. Implement strict QC checks for leak resistance, shape consistency, and heat tolerance. Most international buyers demand certifications such as:

By ensuring product reliability, your aluminum foil container factory will gain trust and long-term clients, especially in export markets.

Although machinery does most of the heavy lifting, skilled operators, maintenance technicians, and packaging workers are essential. Train your staff to handle machines safely, inspect finished goods, and manage inventory efficiently. A dedicated production supervisor can help maintain workflow and reduce downtime.

Once production is in place, focus on reaching your target customers. Build a professional website showcasing your products, factory certifications, and packaging options. Use SEO-optimized product descriptions to attract traffic from search engines.

Additionally, list your business on B2B platforms such as Alibaba, Made-in-China, and Global Sources. Participate in industry expos like the Canton Fair or regional packaging trade shows to meet global aluminium container suppliers and distributors face to face.

Don't forget traditional marketing as well — flyers, catalogs, and local networking can still be very effective in reaching nearby food businesses and restaurants.

With proper certifications and packaging, exporting aluminum foil containers can be a highly profitable venture. Popular destinations include:

Exporting requires attention to customs regulations, documentation, and shipping logistics. Work closely with freight forwarders and use incoterms (FOB, CIF) correctly in your contracts.

Startup costs vary depending on your production scale and automation level. A basic cost breakdown includes:

Typically, profit margins range from 15% to 25%, with many businesses recovering their investment within 12 to 18 months. Maintaining efficient production, strong supplier relationships, and lean operations will boost profitability.

Every business has its hurdles. In this industry, the main challenges include:

However, staying updated with market trends, maintaining strong supplier networks, and adopting automation can help you overcome these obstacles.

In conclusion, the aluminum foil container business presents an excellent opportunity for entrepreneurs looking to enter a high-demand, high-growth industry. Whether you're a newcomer or already in the packaging sector, investing in a aluminium foil container factory can yield long-term success — especially when paired with quality products, a strong marketing strategy, and reliable supplier partnerships.

Start small, stay focused, and scale smart. The global market is waiting.

Want to learn more details, pls look at Aluminium Foil Container Manufacturing Cost.

Related News

Get A Free Quote

Submit Request